Available size

Flat bar:16-200X300-910X3000-5800mm

Round bar:Dia20-600X3000-5800mm

Or as per coustomer requirment customize

Production Time:15-60 days

Basic introduction

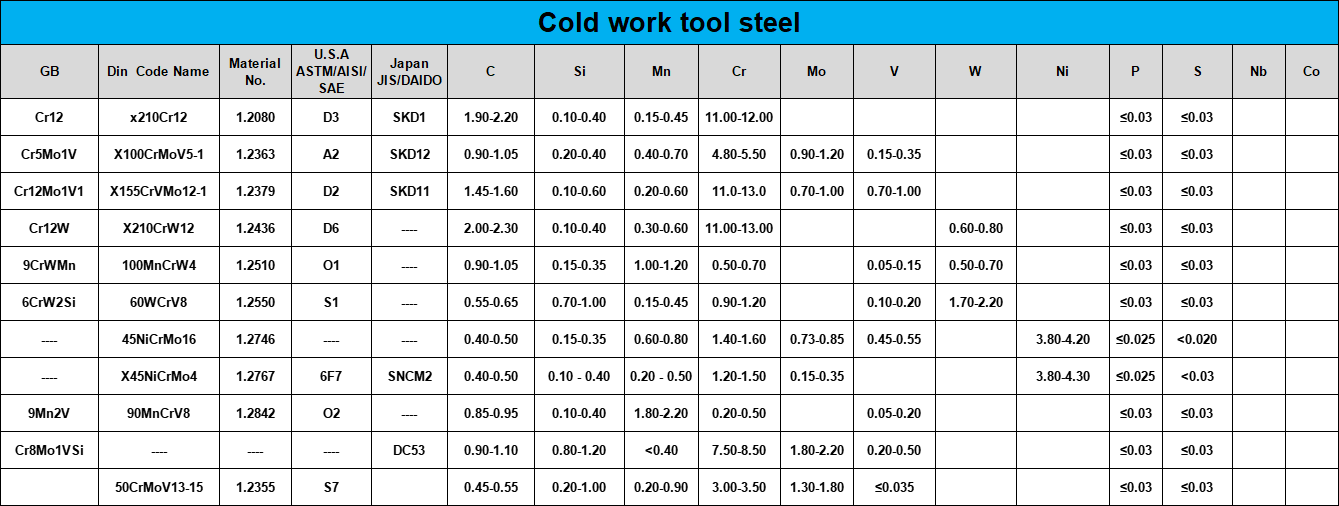

Cold work tool steel focuses on hardness and wear resistance. The carbon content is high, and the alloying elements are mainly to increase the hardenability and improve the wear resistance. Cold work die steel includes dies for blanking (blanking punching dies, trimming dies, punches, scissors), cold heading dies and cold extrusion dies, bending dies and wire drawing dies, etc.

Features

Refined steel by vacuum degassing, inner quality is pure

Good machinability (20% higher machinability than SKD1)

Good hardenability, hardened by air cooling (hardenable cracking)

Excellent wear resistance (can be used as a punching die for stainless steel and high hardness materials)

good toughness

Application

Usage Hardness Usage Usage Hardness

Blanking Die HRC58~62 Advanced Gauge HRC60~65

Forming roll HRC58~63 Thread rolling roll HRC60~63

Cross recessed head screw forming die HRC57~62 Original male die for cold extrusion molding press HRC58~65

Drawing die HRC58~63 Cold heading die HRC58~62

Scissors HRC50~65 Thermosetting resin molding die HRC56~61

Working Conditions

When cold work die steel is working, due to the relatively large deformation resistance of the processed material, the working part of the die bears a lot of pressure, bending force, impact force and friction force. Therefore, the normal reason for the scrapping of cold work dies is generally wear and tear. There are also premature failures due to fracture, collapse force and excessive deformation.

Compared with cutting tool steel, cold work die steel has many things in common. The mold is required to have high hardness and wear resistance, high bending strength and sufficient toughness to ensure the smooth progress of the stamping process. The difference is that the shape of the mold and the processing process are complex. And the friction area is large, and the possibility of wear is high. . So grinding is difficult. Therefore, it is required to have higher wear-resistant molds when working with large punching pressure. Because of the complex shape, it is easy to generate stress concentration, so it requires high toughness; the mold size is large and the shape is complex. Therefore, high hardenability, Less deformation and cracking tendency. In short, the requirements of cold work die steel in terms of hardenability, wear resistance and toughness are higher than that of cutting tool steel. However, the requirements for red hardness are lower or basically not required (because it is cold forming), so Correspondingly, some steel grades suitable for cold work molds have also been formed. For example, high wear-resistant, micro-deformation cold work mold steels and high toughness cold work mold steels have been developed. The following is further explained in conjunction with the selection of relevant steel grades.

Flat bar:16-200X300-910X3000-5800mm

Round bar:Dia20-600X3000-5800mm

Or as per coustomer requirment customize

Production Time:15-60 days

Basic introduction

Cold work tool steel focuses on hardness and wear resistance. The carbon content is high, and the alloying elements are mainly to increase the hardenability and improve the wear resistance. Cold work die steel includes dies for blanking (blanking punching dies, trimming dies, punches, scissors), cold heading dies and cold extrusion dies, bending dies and wire drawing dies, etc.

Features

Refined steel by vacuum degassing, inner quality is pure

Good machinability (20% higher machinability than SKD1)

Good hardenability, hardened by air cooling (hardenable cracking)

Excellent wear resistance (can be used as a punching die for stainless steel and high hardness materials)

good toughness

Application

Usage Hardness Usage Usage Hardness

Blanking Die HRC58~62 Advanced Gauge HRC60~65

Forming roll HRC58~63 Thread rolling roll HRC60~63

Cross recessed head screw forming die HRC57~62 Original male die for cold extrusion molding press HRC58~65

Drawing die HRC58~63 Cold heading die HRC58~62

Scissors HRC50~65 Thermosetting resin molding die HRC56~61

Working Conditions

When cold work die steel is working, due to the relatively large deformation resistance of the processed material, the working part of the die bears a lot of pressure, bending force, impact force and friction force. Therefore, the normal reason for the scrapping of cold work dies is generally wear and tear. There are also premature failures due to fracture, collapse force and excessive deformation.

Compared with cutting tool steel, cold work die steel has many things in common. The mold is required to have high hardness and wear resistance, high bending strength and sufficient toughness to ensure the smooth progress of the stamping process. The difference is that the shape of the mold and the processing process are complex. And the friction area is large, and the possibility of wear is high. . So grinding is difficult. Therefore, it is required to have higher wear-resistant molds when working with large punching pressure. Because of the complex shape, it is easy to generate stress concentration, so it requires high toughness; the mold size is large and the shape is complex. Therefore, high hardenability, Less deformation and cracking tendency. In short, the requirements of cold work die steel in terms of hardenability, wear resistance and toughness are higher than that of cutting tool steel. However, the requirements for red hardness are lower or basically not required (because it is cold forming), so Correspondingly, some steel grades suitable for cold work molds have also been formed. For example, high wear-resistant, micro-deformation cold work mold steels and high toughness cold work mold steels have been developed. The following is further explained in conjunction with the selection of relevant steel grades.