Features

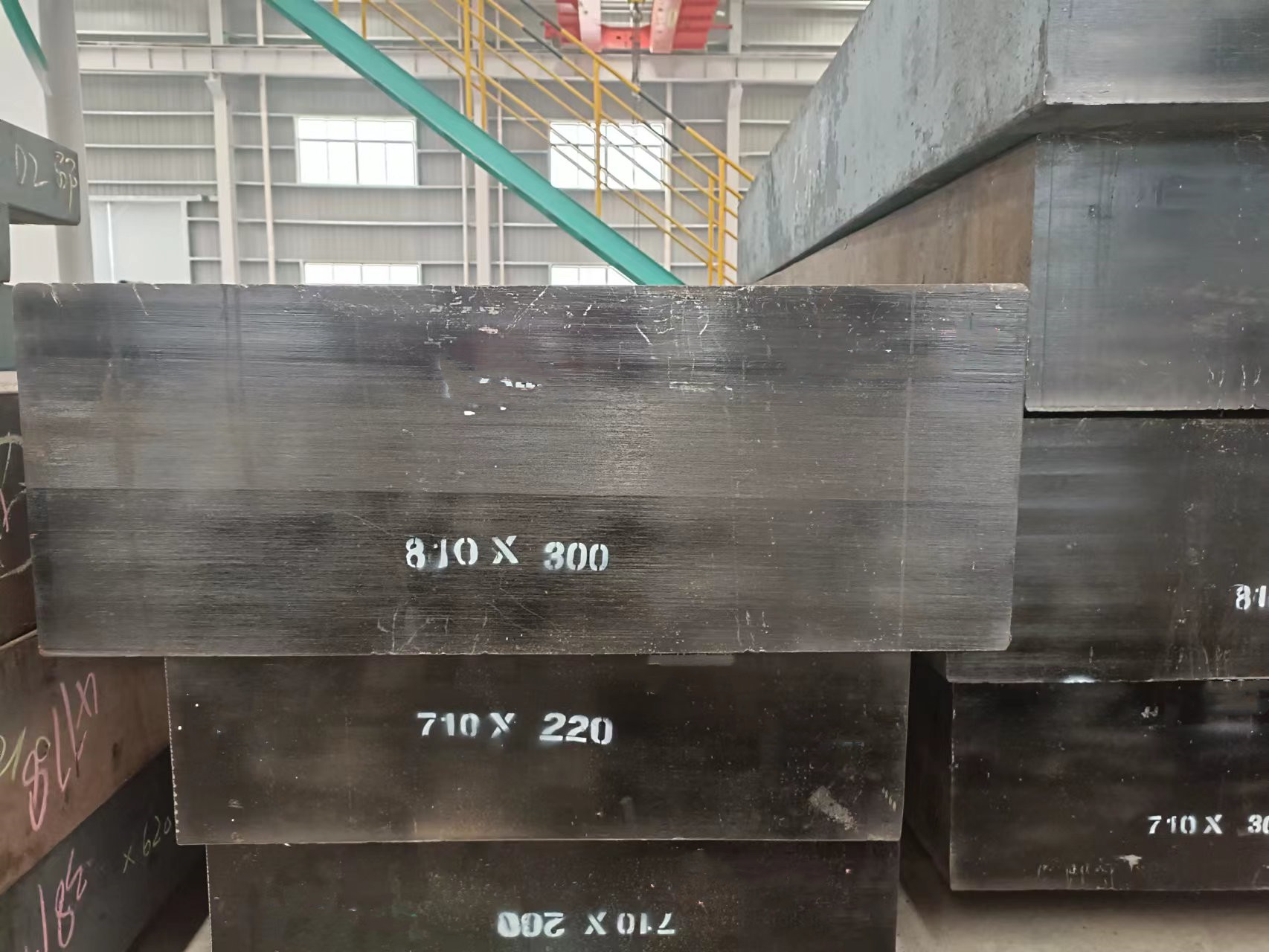

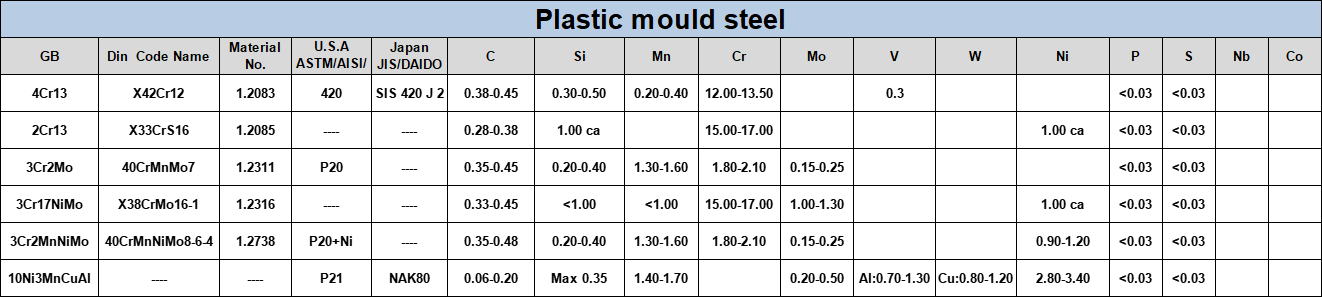

1. The steel used for plastic molds covers a wide range, from ordinary steel to special steel. This is more obvious in the early days of plastic molds, and now it has become more formal and advanced. Special steel has formed its own system. The chemical composition of mold steel is basically the same as that of alloy tool steel, but its metallurgical quality is higher, and its processing is excellent, which is beneficial to heat treatment.

2. The performance requirements of plastic mold steel are strict, and the heat treatment is difficult.

3. In order to avoid deformation or other heat treatment problems of mold parts during the toughening process, it is common for mold steel to be supplied to the market in the form of pre-hardening.

4. Plastic products with petrochemical products as raw materials have different degrees of corrosiveness, so corrosion-resistant steel is also widely used.

5. With the application of pre-hardened steel and non-quenched and tempered steel, easy machinability is also a feature of plastic mold steel.

Application

1. Develop materials that are easy to process and polish

With the production of precision parts such as optical discs, magnetic disks, and prisms, the requirements for easy-to-machine mirror steel have increased. This kind of steel contains less non-metallic impurities, the metallographic structure is fine and uniform, and there is no fiber orientation. It is the main development direction of plastic mold steel.

2. Corrosion resistant steel

During the long-term operation and maintenance of the mold, it is easy to rust and corrode, and with the addition of various components in plastic molding, the mold is more susceptible to corrosion. Therefore, it is required to improve the corrosion resistance of the base metal body, and some corrosion-resistant stainless steel materials have been developed.

3. Maraging alloy steel

This kind of steel has sufficient mechanical properties and outstanding technological properties, especially high strength, toughness, wear resistance, and low thermal expansion coefficient. It is a good steel for making injection molds, but it is expensive.

4. Carbide

It is mainly used to make molds with high requirements on life and large batches of parts.

1. The steel used for plastic molds covers a wide range, from ordinary steel to special steel. This is more obvious in the early days of plastic molds, and now it has become more formal and advanced. Special steel has formed its own system. The chemical composition of mold steel is basically the same as that of alloy tool steel, but its metallurgical quality is higher, and its processing is excellent, which is beneficial to heat treatment.

2. The performance requirements of plastic mold steel are strict, and the heat treatment is difficult.

3. In order to avoid deformation or other heat treatment problems of mold parts during the toughening process, it is common for mold steel to be supplied to the market in the form of pre-hardening.

4. Plastic products with petrochemical products as raw materials have different degrees of corrosiveness, so corrosion-resistant steel is also widely used.

5. With the application of pre-hardened steel and non-quenched and tempered steel, easy machinability is also a feature of plastic mold steel.

Application

1. Develop materials that are easy to process and polish

With the production of precision parts such as optical discs, magnetic disks, and prisms, the requirements for easy-to-machine mirror steel have increased. This kind of steel contains less non-metallic impurities, the metallographic structure is fine and uniform, and there is no fiber orientation. It is the main development direction of plastic mold steel.

2. Corrosion resistant steel

During the long-term operation and maintenance of the mold, it is easy to rust and corrode, and with the addition of various components in plastic molding, the mold is more susceptible to corrosion. Therefore, it is required to improve the corrosion resistance of the base metal body, and some corrosion-resistant stainless steel materials have been developed.

3. Maraging alloy steel

This kind of steel has sufficient mechanical properties and outstanding technological properties, especially high strength, toughness, wear resistance, and low thermal expansion coefficient. It is a good steel for making injection molds, but it is expensive.

4. Carbide

It is mainly used to make molds with high requirements on life and large batches of parts.