Available size

Flat bar:16-30X300-910X3000-5800mm

Round bar:Dia20-800X3000-5800mm

Or as per coustomer requirment customize

Production Time:15-60 days

Basic introduction

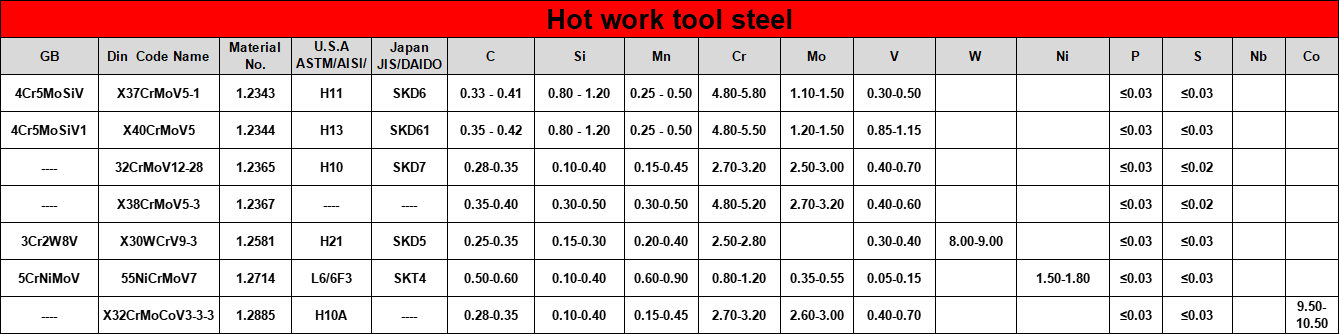

Hot work tool steel has appropriate hardness requirements, focusing on red hardness, thermal conductivity, and wear resistance.

Therefore, the carbon content is low, and the alloy elements are mainly used to increase the hardenability, wear resistance and red hardness.

Working Environment:

Hot work die steel includes hammer forging die, hot extrusion die and die casting die. As mentioned above, the main feature of the working conditions of the hot work die is contact with the hot metal, which is the main difference from the working conditions of the cold work die. Therefore, it will bring the following two problems:

(1) The metal on the surface of the cavity is heated. Usually when the hammer forging die is working, the surface temperature of the die cavity can reach above 300~400℃. For example, when die casting ferrous metal, the cavity temperature can reach more than 1000 ℃. Such a high use temperature will significantly reduce the surface hardness and strength of the cavity, and it is prone to stacking during use. For this reason, the basic performance requirements for hot mold steel are high thermoplastic deformation resistance, including high temperature hardness and high temperature strength, high thermoplastic deformation resistance, which actually reflects the high tempering stability of the steel. From this, the first way to alloy the hot die steel can be found, that is, adding alloying elements such as Cr, W, Si. can improve the tempering stability of the steel.

(2) Thermal fatigue (cracking) occurs in the surface metal of the cavity. The working characteristics of the hot mold are intermittent. After each time the hot metal is formed, the surface of the mold cavity must be cooled with water, oil, air and other media. Therefore, the working state of the hot mold is repeated heating and cooling, so that the surface metal of the mold cavity undergoes repeated thermal expansion and contraction, that is, repeated tensile and compressive stress. As a result, cracks appear on the surface of the mold cavity, which is called thermal fatigue. Therefore, the second basic performance requirement for hot die steel is put forward. That is, it has high thermal fatigue resistance.

Generally speaking, the main factors that affect the thermal fatigue resistance of steel are: ①The thermal conductivity of steel. The high thermal conductivity of steel can reduce the heating degree of the metal on the surface of the mold, thereby reducing the thermal fatigue tendency of the steel. It is generally believed that the thermal conductivity of steel is related to the carbon content. When the carbon content is high, the thermal conductivity is low, so high carbon steel should not be used for hot work die steel. In production, medium carbon steel (C0.3% 5~0.6%) is usually used with too low carbon content, which will lead to a decrease in the hardness and strength of the steel. It is also unfavorable.

②The critical point of steel affects. Generally, the higher the critical point (Acl) of the steel, the lower the thermal fatigue tendency of the steel. Therefore, the critical point of the steel is generally increased by adding alloying elements Cr, W, Si, etc. Thereby improving the thermal fatigue resistance of steel.

Flat bar:16-30X300-910X3000-5800mm

Round bar:Dia20-800X3000-5800mm

Or as per coustomer requirment customize

Production Time:15-60 days

Basic introduction

Hot work tool steel has appropriate hardness requirements, focusing on red hardness, thermal conductivity, and wear resistance.

Therefore, the carbon content is low, and the alloy elements are mainly used to increase the hardenability, wear resistance and red hardness.

Working Environment:

Hot work die steel includes hammer forging die, hot extrusion die and die casting die. As mentioned above, the main feature of the working conditions of the hot work die is contact with the hot metal, which is the main difference from the working conditions of the cold work die. Therefore, it will bring the following two problems:

(1) The metal on the surface of the cavity is heated. Usually when the hammer forging die is working, the surface temperature of the die cavity can reach above 300~400℃. For example, when die casting ferrous metal, the cavity temperature can reach more than 1000 ℃. Such a high use temperature will significantly reduce the surface hardness and strength of the cavity, and it is prone to stacking during use. For this reason, the basic performance requirements for hot mold steel are high thermoplastic deformation resistance, including high temperature hardness and high temperature strength, high thermoplastic deformation resistance, which actually reflects the high tempering stability of the steel. From this, the first way to alloy the hot die steel can be found, that is, adding alloying elements such as Cr, W, Si. can improve the tempering stability of the steel.

(2) Thermal fatigue (cracking) occurs in the surface metal of the cavity. The working characteristics of the hot mold are intermittent. After each time the hot metal is formed, the surface of the mold cavity must be cooled with water, oil, air and other media. Therefore, the working state of the hot mold is repeated heating and cooling, so that the surface metal of the mold cavity undergoes repeated thermal expansion and contraction, that is, repeated tensile and compressive stress. As a result, cracks appear on the surface of the mold cavity, which is called thermal fatigue. Therefore, the second basic performance requirement for hot die steel is put forward. That is, it has high thermal fatigue resistance.

Generally speaking, the main factors that affect the thermal fatigue resistance of steel are: ①The thermal conductivity of steel. The high thermal conductivity of steel can reduce the heating degree of the metal on the surface of the mold, thereby reducing the thermal fatigue tendency of the steel. It is generally believed that the thermal conductivity of steel is related to the carbon content. When the carbon content is high, the thermal conductivity is low, so high carbon steel should not be used for hot work die steel. In production, medium carbon steel (C0.3% 5~0.6%) is usually used with too low carbon content, which will lead to a decrease in the hardness and strength of the steel. It is also unfavorable.

②The critical point of steel affects. Generally, the higher the critical point (Acl) of the steel, the lower the thermal fatigue tendency of the steel. Therefore, the critical point of the steel is generally increased by adding alloying elements Cr, W, Si, etc. Thereby improving the thermal fatigue resistance of steel.